Samsung patent application US20100320515 proposes a single-electron JFET-like structure (SEFET) to make small and sensitive pixel:

The photoelectrons are collected in N-doped area and drift close to the p-channel area due to the doping gradient. Then the collected electrons modulate the channel conduction by changing the N-gate potential:

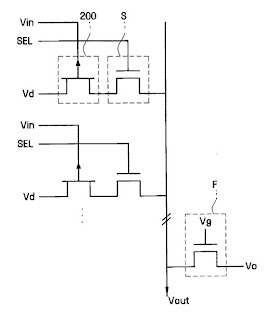

Few different readout sbhemes are proposed, for example, this one (Vin is N-doped area voltage):

The SEFET pixel is said to be able to achieve a conversion gain of 1-9mV/e, as measured at the N-doped gate. Less than 1um pixel size is claimed to be possible.

One thing I was unable to find in the Samsung application is how the N-doped gate is reset before the integration starts.

Pixart application US20100320552 proposes to place color filter on top of microlens to improve the light passage through the metal stake:

"Compared with the prior art, such arrangement is advantageous in that the micro lens 18 is located much closer to the photo diode 12. As a result, the micro lens 18 has a wider chief ray angle, and the photo diode 12 has a better light collection efficiency."

Sony Aims to Capture 30% of Mobile Sensor Market

Forbes quotes Sony saying that it intends to win 30% of the market for image sensors used in mobile phones, up from an expected 10% for the fiscal year ended March 2011.

Sony to Invest $1.2B to Double Image Sensor Production

Reuters: Sony will invest $1.2B in the next financial year to double its output of image sensors. The sum includes a deal announced last week to buy back a semiconductor production line from Toshiba, which has been estimated by an industry source at 50 billion yen ($600 million).

Sony will take advantage of a Japanese government subsidy for environmentally friendly businesses to help with the investment, it said in a statement but declined to say how much that would be.

It will convert part of the plant in Nagasaki, southern Japan, for the production of CMOS sensors and invest in wafer processing equipment for CMOS image sensors. The investment will bring its total production of image sensors, including CCD and CMOS types, to 50,000 300mm wafers a month by March 2012.

Market Watch and Business Week too present their versions of the story.

Update: Sony published an official PR here.

"Sony Corporation ("Sony") today announced that Sony plans to invest approximately 100 billion yen in Sony Semiconductor Kyushu Corporation's Nagasaki Technology Center ("Nagasaki TEC") in the fiscal year ending March 31, 2012, to increase the production capacity for CMOS image sensors.

This investment plan includes (i) the transfer of the semiconductor fabrication facilities from Toshiba Corporation ("Toshiba") contemplated under a non-binding memorandum of understanding between Sony and Toshiba jointly announced on December 24, 2010, (ii) refurbishment of a part of the above semiconductor fabrication facilities into new wafer lines capable of manufacturing CMOS image sensors, and (iii) refurbishment and equipment of a part of production facilities at Nagasaki TEC Building 3 for wafer processing to differentiate Sony's CMOS image sensors with Sony's independently developed unique technologies. Through the investment plan, Sony will utilize a governmental subsidy to be provided by the Ministry of Economy, Trade and Industry in Japan - the "subsidy for programs to promote siting low-carbon job-creating industries" - mainly in connection with the investment mentioned in (iii) above."

Sony will take advantage of a Japanese government subsidy for environmentally friendly businesses to help with the investment, it said in a statement but declined to say how much that would be.

It will convert part of the plant in Nagasaki, southern Japan, for the production of CMOS sensors and invest in wafer processing equipment for CMOS image sensors. The investment will bring its total production of image sensors, including CCD and CMOS types, to 50,000 300mm wafers a month by March 2012.

Market Watch and Business Week too present their versions of the story.

Update: Sony published an official PR here.

"Sony Corporation ("Sony") today announced that Sony plans to invest approximately 100 billion yen in Sony Semiconductor Kyushu Corporation's Nagasaki Technology Center ("Nagasaki TEC") in the fiscal year ending March 31, 2012, to increase the production capacity for CMOS image sensors.

This investment plan includes (i) the transfer of the semiconductor fabrication facilities from Toshiba Corporation ("Toshiba") contemplated under a non-binding memorandum of understanding between Sony and Toshiba jointly announced on December 24, 2010, (ii) refurbishment of a part of the above semiconductor fabrication facilities into new wafer lines capable of manufacturing CMOS image sensors, and (iii) refurbishment and equipment of a part of production facilities at Nagasaki TEC Building 3 for wafer processing to differentiate Sony's CMOS image sensors with Sony's independently developed unique technologies. Through the investment plan, Sony will utilize a governmental subsidy to be provided by the Ministry of Economy, Trade and Industry in Japan - the "subsidy for programs to promote siting low-carbon job-creating industries" - mainly in connection with the investment mentioned in (iii) above."

Shoji Kawahito Received Takayanagi Memorial Award

Shizuoka University Professor Dr. Shoji Kawahito has received the 24th Takayanagi Memorial Award for his contribution to development of high-performance and high-functionality imaging devices. (Kenjiro Takayanagi is the father of Japanese television.)

Chipworks Analyzes Samsung 1.4um BSI Sensor

Chipworks got a hold of Samsung S5K4E5 - a 1.4um pixel-based 5MP 1/4-inch mobile sensor. This is said to be Samsung's first BSI sensor with TSV technology. Samsung has indicated that it uses a lower-cost bulk silicon manufacturing process which they estimated to be 4x to 5x lower wafer cost compared with SOI.

The reverse engineering is ongoing. Meanwhile Chipworks released a photo of the sensor's backside:

The reverse engineering is ongoing. Meanwhile Chipworks released a photo of the sensor's backside:

Optrima to Mass Produce Consumer ToF-Based 3D/RGB/Audio Camera

Business Wire: Optrima announced it has reached mass-production quality for a consumer electronics 3D, video (HD) and audio camera. The camera, the result of collaboration with its partner Namuga, is said to be the world’s first embedded 3D camera with high definition RGB.

"The availability of a high-performance, low-cost 3D camera with built-in audio and video will dramatically contribute to the adoption of 3D gesture-based interfaces and applications by consumers," said Andre Miodezky, CEO of Optrima. "We’re very excited to be the first company to bring such a product to the market and look forward to working with our customers to bring the product to the market in 2011."

Consumers will be able to utilize the camera for gesture-based applications such as video games, interactive, touch- and controller-less user interfaces, as well as video conferencing and other exciting new user experiences, whether on desktop computer systems or connected TVs.

"The availability of a high-performance, low-cost 3D camera with built-in audio and video will dramatically contribute to the adoption of 3D gesture-based interfaces and applications by consumers," said Andre Miodezky, CEO of Optrima. "We’re very excited to be the first company to bring such a product to the market and look forward to working with our customers to bring the product to the market in 2011."

Consumers will be able to utilize the camera for gesture-based applications such as video games, interactive, touch- and controller-less user interfaces, as well as video conferencing and other exciting new user experiences, whether on desktop computer systems or connected TVs.

Sony to Buy Back Image Sensor Fab from Toshiba

Reuters: Sony plans to buy back a Nagasaki semiconductor plant from Toshiba Corp for about 50 billion yen ($597.2 million) to double output capacity for CMOS image sensors used in smartphones and other devices, the Nikkei business daily reported.

Sony sold it to Toshiba in 2008. Acquiring the plant back will double Sony's image sensor output capacity to the equivalent of about 40,000 wafers a month, the daily said.

By boosting output and lowering production costs, Sony aims to catch up with such firms Samsung and U.S. players in the CMOS sensor market, Nikkei said.

Update: EETimes publishes an article with details about the March 2008 complex deal between Toshiba and Sony.

Update #2: Reuters quotes Sony Executive Deputy President Hiroshi Yoshioka saying in an interview this week that it was in the process of deciding how to cover a shortage in CMOS sensor output capacity.

Update #3: Sony published an official PR here.

Nagasaki Semiconductor Manufacturing Corporation (NSM), which was established in March 2008 and is located in the Nagasaki Technology Center of Sony Semiconductor Kyushu Corporation ("SCK"), has been manufacturing the high-performance "Cell Broadband Engine" processor, the graphics engine "RSX" and other high-performance semiconductors and leading-edge SoCs for applications in digital consumer products of Toshiba and Sony. The facilities to be transferred would be the fabrication facilities and equipment for the 300 mm wafer line located within the Nagasaki Technology Center purchased by Toshiba from Sony and SCK and leased to NSM in 2008 and other facilities that Toshiba and Sony will agree to transfer among those in which Toshiba invested in connection with the operation by NSM after the purchase.

Current NSM ownership: Toshiba 60%, Sony 20% and SCEI 20%

Number of employees: Approximately 460 as of December 1, 2010

Sony sold it to Toshiba in 2008. Acquiring the plant back will double Sony's image sensor output capacity to the equivalent of about 40,000 wafers a month, the daily said.

By boosting output and lowering production costs, Sony aims to catch up with such firms Samsung and U.S. players in the CMOS sensor market, Nikkei said.

Update: EETimes publishes an article with details about the March 2008 complex deal between Toshiba and Sony.

Update #2: Reuters quotes Sony Executive Deputy President Hiroshi Yoshioka saying in an interview this week that it was in the process of deciding how to cover a shortage in CMOS sensor output capacity.

Update #3: Sony published an official PR here.

Nagasaki Semiconductor Manufacturing Corporation (NSM), which was established in March 2008 and is located in the Nagasaki Technology Center of Sony Semiconductor Kyushu Corporation ("SCK"), has been manufacturing the high-performance "Cell Broadband Engine" processor, the graphics engine "RSX" and other high-performance semiconductors and leading-edge SoCs for applications in digital consumer products of Toshiba and Sony. The facilities to be transferred would be the fabrication facilities and equipment for the 300 mm wafer line located within the Nagasaki Technology Center purchased by Toshiba from Sony and SCK and leased to NSM in 2008 and other facilities that Toshiba and Sony will agree to transfer among those in which Toshiba invested in connection with the operation by NSM after the purchase.

Current NSM ownership: Toshiba 60%, Sony 20% and SCEI 20%

Number of employees: Approximately 460 as of December 1, 2010

Teledyne to Acquire DALSA

Business Wire: Teledyne and DALSA jointly announce that they have entered into a definitive agreement that provides for the acquisition of DALSA by a wholly-owned subsidiary of Teledyne. The aggregate value for the transaction is approximately CAD $341 million, taking into account DALSA’s stock options and net cash as of September 30, 2010. That represents a premium of 27.7% over the twenty-day volume weighted average trading price.

Headquartered in Waterloo, Ontario, DALSA has approximately 1,000 employees worldwide. For the twelve months ended September 30, 2010, DALSA had sales of approximately CAD $201 million.

"I view this transaction as a natural evolution for DALSA and a positive development for all DALSA stakeholders including shareholders, employees, executives, local communities, customers and vendors," commented Dr. Savvas Chamberlain, Chairman of the Board and Founder of DALSA. "The decision to be a part of a larger organization recognizes that in order for DALSA to become a billion dollar company, we need to team up with an industry leader with complementary technologies. Finally, as the founder of the company, I am pleased to see DALSA’s name live on, in its new incarnation as Teledyne DALSA."

"Teledyne and DALSA are each acknowledged leaders in digital imaging technology but our product lines and customer bases are almost entirely complementary. For example, DALSA produces among the world’s most advanced visible light imaging sensors and cameras for commercial applications, while Teledyne produces extreme resolution infrared sensors and subsystems primarily for government applications," said Dr. Robert Mehrabian, Chairman, President and CEO of Teledyne. "The combined strengths of Teledyne’s and DALSA’s leading imaging technologies will allow us to develop new infrared and visible light products that serve our respective markets and customers."

The definitive agreement contains a termination fee in the amount of approximately CAD $10.2 million, which is payable by DALSA to Teledyne in certain circumstances if the transaction is not completed. DALSA and Teledyne expect that the transaction will close in February 2011.

Update: EETimes too published an article with some more background about DALSA and Teledyne.

Headquartered in Waterloo, Ontario, DALSA has approximately 1,000 employees worldwide. For the twelve months ended September 30, 2010, DALSA had sales of approximately CAD $201 million.

"I view this transaction as a natural evolution for DALSA and a positive development for all DALSA stakeholders including shareholders, employees, executives, local communities, customers and vendors," commented Dr. Savvas Chamberlain, Chairman of the Board and Founder of DALSA. "The decision to be a part of a larger organization recognizes that in order for DALSA to become a billion dollar company, we need to team up with an industry leader with complementary technologies. Finally, as the founder of the company, I am pleased to see DALSA’s name live on, in its new incarnation as Teledyne DALSA."

"Teledyne and DALSA are each acknowledged leaders in digital imaging technology but our product lines and customer bases are almost entirely complementary. For example, DALSA produces among the world’s most advanced visible light imaging sensors and cameras for commercial applications, while Teledyne produces extreme resolution infrared sensors and subsystems primarily for government applications," said Dr. Robert Mehrabian, Chairman, President and CEO of Teledyne. "The combined strengths of Teledyne’s and DALSA’s leading imaging technologies will allow us to develop new infrared and visible light products that serve our respective markets and customers."

The definitive agreement contains a termination fee in the amount of approximately CAD $10.2 million, which is payable by DALSA to Teledyne in certain circumstances if the transaction is not completed. DALSA and Teledyne expect that the transaction will close in February 2011.

Update: EETimes too published an article with some more background about DALSA and Teledyne.

Ambarella iOne Supports 32MP Imaging on Android Platform

Business Wire: Ambarella announced the iOne SoC HD camera for Android OS platform. The iOne is based on a triple ARM CPU architecture. Dual-core 1-GHz ARM Cortex A9 CPUs provide the horsepower to run Android applications while a third 533-MHz ARM-11 handles real-time camera tasks and enables camera boot time of under one second.

The camera part supports simultaneous still photography and HD video recording - up to 32MP still image processing with high speed capture of 5MP images at 30 fps, and Electronic Image Stabilization (EIS) with CMOS sensor rolling shutter correction.

The iOne SoC is sampling now to early access customers.

Venture Beat adds that cameras with the iOne chips will likely appear in the second half of 2011. Ambarella has 350 employees. Current Ambarella chips are used in devices such as the Sony Bloggie video camera and a host of others.

The camera part supports simultaneous still photography and HD video recording - up to 32MP still image processing with high speed capture of 5MP images at 30 fps, and Electronic Image Stabilization (EIS) with CMOS sensor rolling shutter correction.

The iOne SoC is sampling now to early access customers.

Venture Beat adds that cameras with the iOne chips will likely appear in the second half of 2011. Ambarella has 350 employees. Current Ambarella chips are used in devices such as the Sony Bloggie video camera and a host of others.

Varioptic Aims to Raise EUR 10 million in 2011

ReportLinker: Varioptic aims to raise EUR 10 million (USD 13.1M) during the first half of 2011 to finance a production capacity increase, French daily Les Echos wrote, quoting CEO Hamid Farzaneh.

Microsoft to Improve Kinect Resolution

Eurogamer: Microsoft is working to improve the accuracy of Xbox Kinect so that it could detect finger movement and hand rotation. Kinect depth sensor is currently running at 320x240 resolution and 30fps speed, while its hardware could support 640x480 resolution. The issue relates to the USB controller interface, Eurogamer said. It is capable of around 35MB/s, but it only uses around 15/16MB/s. This artificial limit is in place because multiple USB devices can be used at once on Xbox 360.

Now Microsoft is working on a technology to allow greater throughput in this regard. At a 640x480 depth sensor resolution Kinect could begin to detect fingers and hand rotation – an effective quadrupling of its accuracy.

Now Microsoft is working on a technology to allow greater throughput in this regard. At a 640x480 depth sensor resolution Kinect could begin to detect fingers and hand rotation – an effective quadrupling of its accuracy.

EU Key Enabling Technologies in Imaging

EU Expert Group on Key Enabling Technologies has had a talk on imaging technologies in Europe. Leti-Minatec presented a proposal on the important areas to develop:

Cypress Designs Image Sensors for ARRI

Business Wire: Cypress announced that its CMOS image sensor has been designed into 35 mm ALEXA digital motion picture camera from ARRI (Arnold & Richter Cine Technik GmbH), headquartered in Germany. A Cypress custom CMOS imager sensor also was designed into ARRI’s ARRIFLEX D20/D21 digital motion picture camera, which preceded the ALEXA.

TSMC 0.9um Pixel/Process Presentation

Somebody put all IEDM 2010 papers into open access. Image sensor session papers start with S14P. One of the most interesting papers is TSMC invited presentation S14P01.PDF:

A Leading-Edge 0.9μm Pixel CMOS Image Sensor Technology with Backside Illumination: Future Challenges for Pixel Scaling (Invited)

S.G. Wuu, C.C. Wang, B.C. Hseih, Y.L. Tu, C.H. Tseng, T.H. Hsu, R.S. Hsiao, S. Takahashi, R.J. Lin, C.S. Tsai, Y.P. Chao, K.Y. Chou, P.S. Chou, H.Y. Tu, F. L. Hsueh, L. Tran,

Taiwan Semiconductor Manufacturing Company, Hsin-Chu, Taiwan, R.O.C.

Some interesting quotes from the paper talking about the new N65 300mm BSI process performance:

TSMC uses "Backside antireflection (BARC) layers to further enhance optical sensitivity. "

"wafer-to-wafer ... average thickness variation (are) within 3% of the mean value. ...within-wafer TTV (total thickness variation) for 300mm wafers ... improved to be less than 15%, which is comparable to existing 200mm BSI process as shown in Fig. 3."

One of the problems TSMC observed in small pixels is an increased PRNU level. TSMC team has implemented 4 techniques to improve it:

The PRNU-treated pixel shows 7X PRNU reduction for 1.1um pixel and a 4X reduction on the 0.9um pixel:

Crosstalk is another major challenge in small pixel design. TSMC team has identified CFA spectral crosstalk being the dominant component, followed by optical diffraction, and by electrical crosstalk. TSMC calls for novel ideas in color patterning other than traditional Bayer pattern and new system-level color processing algorithm to reduce the CFA spectral crosstalk problem:

Being with Advasense with our high full well pixel claim, I immediately noticed the full well vs pixel size graph, with 0.9um pixel having just ~30% of 1.4um pixel full well:

And finally, there are color sample pictures from the new 1.1um and 0.9um pixels. 0.9um colors looks a bit pale, but this is somewhat expected at this early design stage:

Congratulations to S.G. Wuu and the whole TSMC team! I'm very impressed by your cutting-edge work!

A Leading-Edge 0.9μm Pixel CMOS Image Sensor Technology with Backside Illumination: Future Challenges for Pixel Scaling (Invited)

S.G. Wuu, C.C. Wang, B.C. Hseih, Y.L. Tu, C.H. Tseng, T.H. Hsu, R.S. Hsiao, S. Takahashi, R.J. Lin, C.S. Tsai, Y.P. Chao, K.Y. Chou, P.S. Chou, H.Y. Tu, F. L. Hsueh, L. Tran,

Taiwan Semiconductor Manufacturing Company, Hsin-Chu, Taiwan, R.O.C.

Some interesting quotes from the paper talking about the new N65 300mm BSI process performance:

TSMC uses "Backside antireflection (BARC) layers

"wafer-to-wafer ... average thickness variation (are) within 3% of the mean value. ...within-wafer TTV (total thickness variation) for 300mm wafers ... improved to be less than 15%, which is comparable to existing 200mm BSI process as shown in Fig. 3."

One of the problems TSMC observed in small pixels is an increased PRNU level. TSMC team has implemented 4 techniques to improve it:

- tightened design rule with advanced lithography (N45/N28…)

- better pixel-to-pixel isolation

- antireflection film optimization

- novel structure for light guidance

The PRNU-treated pixel shows 7X PRNU reduction for 1.1um pixel and a 4X reduction on the 0.9um pixel:

Crosstalk is another major challenge in small pixel design. TSMC team has identified CFA spectral crosstalk being the dominant component, followed by optical diffraction, and by electrical crosstalk. TSMC calls for novel ideas in color patterning other than traditional Bayer pattern and new system-level color processing algorithm to reduce the CFA spectral crosstalk problem:

Being with Advasense with our high full well pixel claim, I immediately noticed the full well vs pixel size graph, with 0.9um pixel having just ~30% of 1.4um pixel full well:

And finally, there are color sample pictures from the new 1.1um and 0.9um pixels. 0.9um colors looks a bit pale, but this is somewhat expected at this early design stage:

Congratulations to S.G. Wuu and the whole TSMC team! I'm very impressed by your cutting-edge work!

Subscribe to:

Posts (Atom)